Issue #12 - The Future of Manufacturing

Welcome to Issue #12 👋

This issue covers the importance of productivity on the shopfloor, robots in warehouses and endless possibilities of 3D printing.

I’m writing this Newsletter now for one year and wanted to take a moment to thank all of you for your interest, loyalty and valuable feedback. I’m really excited to continue the journey and would be very happy if you could take 3min to complete this quick survey which helps me make this newsletter better every time.

I hope you enjoy reading it and if you do so, any feedback, shares or links are much appreciated!

Many thanks especially @Joern (Oee Cloud), Nathan (P9).

Disclaimer: thoughts and opinions expressed in the newsletter are my own.

What I enjoyed reading

#robotics#

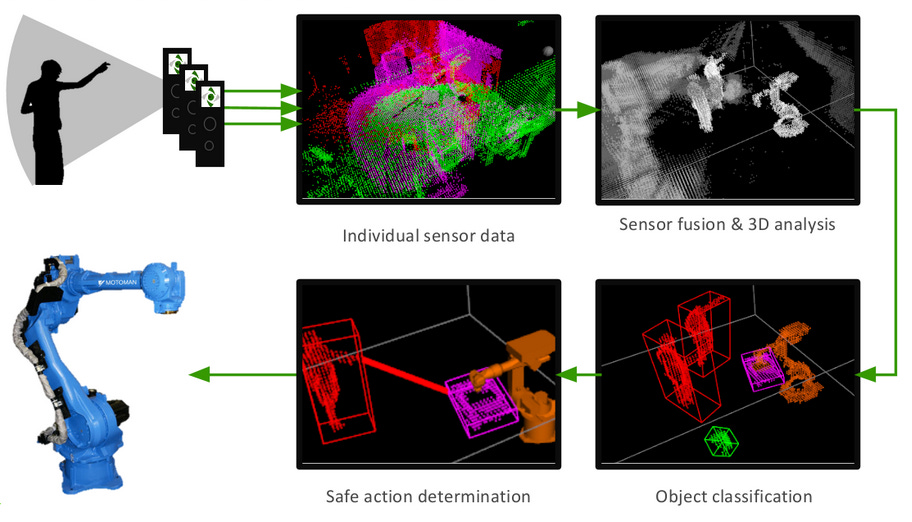

🤖 If you want to have really smart robots they have to have a very good understanding of what’s going on in their environment and then react to their surroundings. Veo Botsis exactly doing this by incorporating advanced computer vision and 3D sensing to make industrial robots more intelligent (here is a short video).

In this post, Clara Vu lays out how she started Veo Bots. She has spent many years before in robotics, first as a software engineer at iRobot then later co-founded Harvest Automation, where they built robotic systems for agriculture. However, she recognized that especially in manufacturing, many engineers have been trying to build useful robotic systems but most of them were very limited so far and factories are still searching for safe and collaborative high-performance industrial robots so she co-founded Veo Bots. I’m sure this will also prevent robots from accidentally hospitalizing workers with bear repellent. Here is how it works:

#3dprinting#

📇 Formlabs, the maker of powerful 3D printing systems, wrote a long summary of its development in 2018. I really like this post since it underlines the impact of 3D printing and the endless possibilities this technology brings us. Some interesting examples they cover in the post:

Northwell Health is using Formlabs to produce patient-specific models that help doctors to prepare for operations.

Together with 3Shape, Formlabs showed how to produce custom earbuds.

Gillette is using Formlabs to make customized 3D printed razor handles:

#productivity#

🔧 Together with A.T. Kearny, Drishti released a report about the state of humans in factories. Even though there is an increasing amount of robots on the shopfloor, 72% of the manufacturing tasks are still performed by humans the study found. Humans continue to perform the majority of critical manufacturing tasks which underlines why I think that employee productivity will be at the heart of the next wave of industrial startups.

One of the biggest problems is the lack of data about manual tasks humans perform in factories that Drishti is tackling by using machine learning and computer vision to collect data about human actions.

#assembly#

🏭 No long description needed.Here is a video about the Tesla 3 general assembly from start to finish, just watch it.

#machinelearning#

🏭 Oden Technologies, an industrial automation company, launched a machine learning and artificial intelligence framework for manufacturing. It can be used for applications to avoid machine failure or eliminate waste. The platform should give manufacturers more simplicity but also more flexibility to deploy intelligent industrial automation since factories are so different and a “one size fits it all” approach usually doesn’t work. If you want to know more details and how it works exactly, here is their whitepaper.

About industrial Startups and Companies

#warehousing#

📦 With all the news about the development in robotics and new robotics companies, it is not surprising that DHL Supply Chain which is the logistics division of DHL will invest $300M to modernize its warehouses. They mostly use robots for collaborative piece picking, for example, withLocus robots and shuttling items across the warehouses. The use of collaborative robots increased the productivity of the workers by over 100%.

#investment#

🤑 The average implementation time for robots is around 3 months. Often robotics software is developed by system integrators which makes it time-consuming and complex to program. Wandelbots offers demonstration based teaching by wearables (e.g. a sensor jacket) and just raised 6.8M led by EQT Ventures with participation from Paua Ventures. The company counts VW and Infineon to its early customers where they use the Wandelbots solution in assembly and logistics (see video here).

#robotics#

🤖 Pick and place items is one of the most popular use cases in warehousing for new robotics companies. And it makes total sense if you think that a typical item is touched four to eleven times before it ships. RightHand Robotics that develops a mechanical gripper based on computer vision just raised $23M in additional funding led by Menlo Ventures with the participation of Matrix Partners and GV. Its technology makes it possible that it can learn to pick items it hasn’t seen before. A bit similar isSoftroboticsthat focuses on highly compliant materials such as food and beverages and counts ScaleVP and ABB as investors.

#investment#

🤑 FactoryFour is developing a manufacturing management software which gives factories more visibility for real-time production tracking and management. It’s kind of a modern MES with more advanced features such as customizable workflows and rule management. The US-based company just raised $5M led by August Capital. It’s quite impressive that the company will probably reach 100 customers by early 2019 and I’m sure this was one of the reasons for the investment.

Additional thoughts on recent development

Use cases vs. platform #development#

If you are building a new product, you have to think in use cases focused on a specific problem, not in technologies or platforms.

Once you have found an initial use case that seems to work, double down on that and make it as easy as possible for new customers to benefit from this use case.

I think a great example isAirtablewhich is a horizontal product with many use cases but by providing a lot of templates they made it super easy to build these use cases: To make onboarding even easier, Airtable comes with a selection of templates grouped into themes (like Event Planning, Real Estate, and Everyday Life), categories (Groups, Clubs, and Hobbies; Book Catalog), and use cases. (Source)

Industrial Landscape #landscape#

I'm working on a new update to my industrial startup landscape. There are now in total ca. 250+ companies in the landscape - here you can see the changes within one year:

Again, Thanks to everybody for supporting this newsletter and for sending me interesting links. As always, any input, shares, and feedback are always warmly welcome 🙏

Robin