Issue #16 - The Future of Manufacturing

👋 Welcome to Issue #16 👋

Topics this time: shortage of talent, more money for robots in warehouses, high ACVs and big OEMs moving to the cloud.

👉 ICYMI: Hannover Messe presentation 👈

In case you missed my presentation Manufacturing the Future at the Hannover Messe, here are the slides. Feedback is always appreciated (shares get lots of ❤️).

💸 Panel: How can startups get out of 'pilot purgatory'?

Together with Robert (b-to-v) and Herbert (Fizyr), we will take part in a panel discussion on the pilot purgatory at the Jungle launch event in Berlin on May 17. Jungle is an open source community of industrial technology startups who get together to discuss, structure and build the "production system of the future” together. Hope to see you there.

As always, I hope you enjoy reading this, any feedback, shares or links are much appreciated!

Many thanks again for the feedback on the NL - I will work and iterate on it.

Disclaimer: thoughts and opinions expressed in the newsletter are my own.

What I've enjoyed reading

#shortageoftalent#

👩🔧 If you follow my writings, you know that I think shortage of talent is one of the most urgent problems in the manufacturing sector. Nidec Corporation, a global manufacturer of electric motors, has an interesting way to solve this by offering "reverse internships". The company partners with universities and offers specialized training programs for graduates where they learn, for example, how to test functions or inspect parts. Students receive a salary and also college credits. Nidec gets a much-needed pipeline to a new generation of technical workers.

#go-to-market#

🔝 Martin Casado (a16z) has written really good blog posts about the challenges of selling to Enterprises and how to overcome these, with this article being my favorite. Recently, he sat down with Matt Truck (First Mark) to talk about go-to-market strategies for Enterprise startups - in a podcast that I highly recommend. My favorite aspect of the interview is the following quote that underlines how important service is:"The traditional way of thinking of services (most VCs) is that they are non-scalable and low margin. The reality is that for every one dollar a customer spends on software, they spend $2 to $3 on services (contract engineering, integration, etc.)."

#pilotpurgatory#

☠️ As we all know, the existence of pilot purgatory is a fact and both startups, and corporates, struggle with it. Tony Saigh has written two blog posts for founders about how to avoid the 'PoC death trap'. His advice is - and I can underline much of this - that founders should focus on adoption rather than logos, build a clear upsell path, never do anything for free (ever!!) and establish consistent pricing early on.

#cloud#

☁️ During the Hannover Messe two interesting announcements made a big splash. First, Volkswagen and Amazon announced that they are teaming up to create an industrial cloud for all 122 VW factories. Long term, they also want to integrate their 1500 suppliers and partner companies. This is a big step into the manufacturing industry for Amazon.

Second, Microsoft is teaming up with BMW to build an IoT-focused open manufacturing platform. BMW already has a few thousand machines running on Azure Cloud and they want to make their solutions available to other companies. This is obviously great for Microsoft - but I wonder how SAP or IBM are dealing with it?!

About industrial Startups and Companies

#landscape#

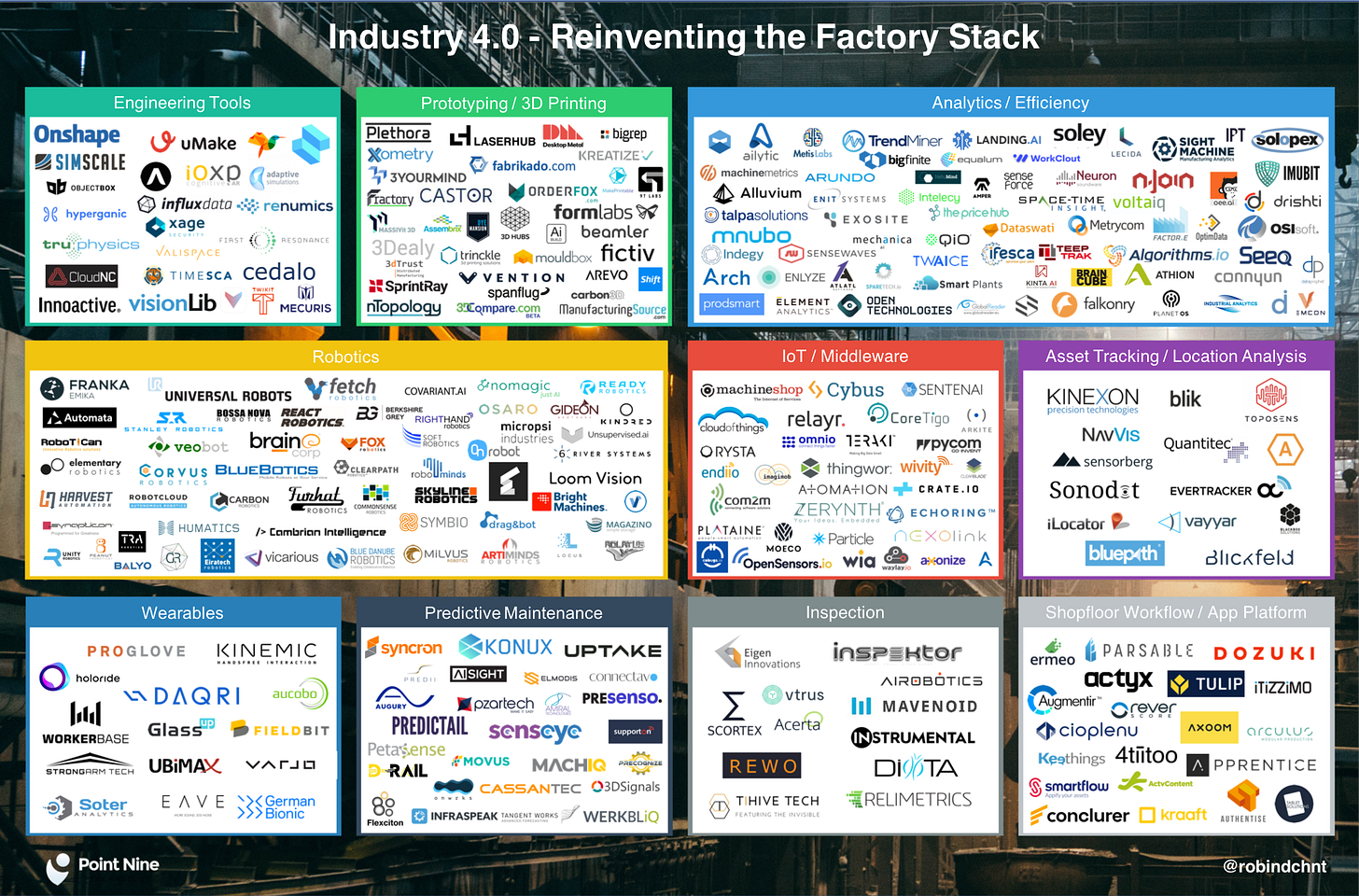

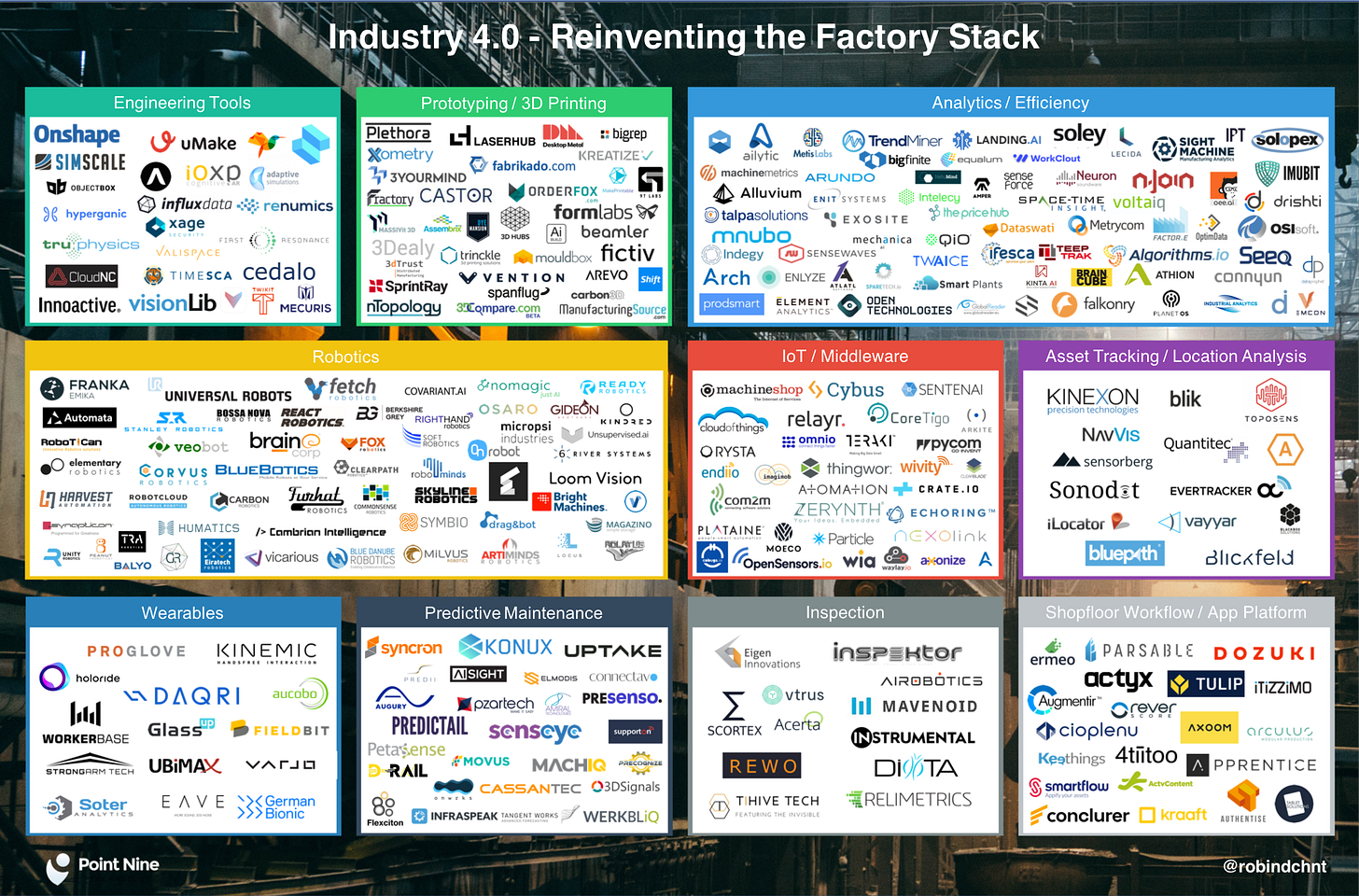

💥 I've updated my Industry 4.0 landscape, counting more than 300 companies now 💥

#fundraising#

🤑Sight Machine, a manufacturing analytics solution provider, just raised nearly $30M with the goal of becoming the "SAP of industrial data". The round was led by LS Group, a South Korean conglomerate and the company counts Nissan and Heineken to its customers. The core of their solution is that they take structured and unstructured manufacturing data and then contextualize and model that data into digital twins for real-time analysis and visualization. #fundraising#

🤑 Locus Robotics, a producer of smart warehouse robots, recently raised $26M led by Zebra Ventures and Scale Venture Partners, already an investor in the company. Their robots work similarly to Amazon’s Kiva and Fetch robots and help companies boost productivity and reduce costs. They plan to start operations in Europe this year and in Asia later on. DHL is one of its biggest customers.

#shutdown#

🤖 After the shutdown of Rethink Robotics, another robotic startup - Anki - that raised more than $200M from top investors such as a16z and made close to $100M in revenue in 2017 has had to shut down, too. One reason is that a financing round fell through last-minute and they weren't able to bridge the financing gap. The company was well-known for its smartphone-controlled car system Anki Drive and other small robots targeted at consumers.

#pick'n'place#

🤖 You may know the famous videos of Boston Dynamics robots such as the 'wildcat'; recently the company has also developed robots that can work in warehouses, e.g. to pick and place parcels. To do so, the company acquired Kinema Systems, a developer of 3D imaging solutions for pick-and-place logistics. As you can see in this video, the Handle robot can place boxes onto a pallet relatively quickly.

Additional thoughts on recent development

What are "good" ACVs? #sales#

One of the questions I get a lot from founders is: What are "good" annual contract values (ACVs)?

If you are selling to Enterprises (a.k.a. hunting elephants), investors expect that you can charge ACVs of at least $100k. Getting €10-20k ACVs from the likes of Bosch, BMW or GE makes it definitely hard to scale. If these large enterprises see a true value in your solution, they should be able to pay up for it.

So, what do you have to provide in order to be able to charge ACVs north of $100k? The answer is obviously "it depends", but as a good rule of thumb, you can usually monetize 10-20% of the yearly savings you are generating.

That means, if you save a factory $200-300k per year, you can probably only charge $20-30k ACVs. This is obviously not great. In order to get to $100k ACVs, you have to save the factory at least $1M per year. If you have this in mind, I would encourage you to focus on high-value use cases and spend time with those customers where you are able to get into that range.

Industrial Landscape #landscape#

As mentioned, I recently updated my industrial startup landscape. There are now in total 300+ companies in the landscape:

Again, Thanks to everybody for supporting this newsletter and for sending me interesting links. As always, any input, shares, and feedback are always warmly welcome 🙏

Robin