Issue #28 - The Future of Manufacturing

Topics this time: women in manufacturing, more industrial venture funds, new factories and growing areas within manufacturing.

👋 Welcome to Issue #28 👋

An Update on Community & Events:

🆕 Virtual Event: Together with Marco, Senior Manager at Zeiss, we’re doing a virtual event about: Shopfloor IT for discrete manufacturing - a primer for non-technical people. The goal is to provide a simple overview of the IT landscape within factories and how it has grown over time. We have a few slots left, please register here if you want to participate.

👪 Community for Innovation Managers: As mentioned last time, I started building a community for innovation managers. This community is for people who work on the digital transformation in manufacturing companies, coordinate and drive digitization projects, and scout new ideas. I invited 50+ people already and will invite more people over the next few weeks. You can join the waitlist here or forward it to somebody you think should be part of this global community. Please note, building a diverse community is a key priority for me.

“Thanks for this again, it’s an awesome network. Already some really interesting contacts for some of the subjects we’re trying to really explore this year.” (M.T.)

🆕 Online Event: On the 17th of March, I will give a talk (in German) at the Days of Metal organized by Laserhub. You can find more info here.

Got a friend or colleague interested in the future of manufacturing? Help me spread the word by sharing the newsletter if you like it!

What I’ve enjoyed reading 👇

👩🏭 Women are critical to manufacturing’s future.

The manufacturing industry has a massive problem with diversity. Women are underrepresented in the manufacturing workforce and account for roughly one-third of manufacturing workers. Closing the manufacturing’s gender gap is also key to closing the skills gap. While the tech industry is increasingly paying attention to diversity, I think manufacturing does not do enough to diversify its workforce. As explained in this article, research shows that gender diversity helps manufacturing companies to build a culture that is more innovative. There are a few initiatives out there that promote the role of women in manufacturing such as Femtec in Germany and the STEP Ahead Women’s Initiative by the Manufacturing Institute. This is a good start but it’s not enough. We need everybody working on solving this problem and go the extra mile. A simple example: if you run an event, please avoid the typical white-man panels. I know it’s not easy in this industry but I’m so tired of this.

👉 Personal opinion: I’m thinking about how I can contribute with this newsletter and other initiatives on solving manufacturing's diversity problem. Creating awareness is a good start but I want to do more. So if you have any ideas in mind or people I should talk to, I’m all ears. 🤖 Starship shipped one million autonomous deliveries.

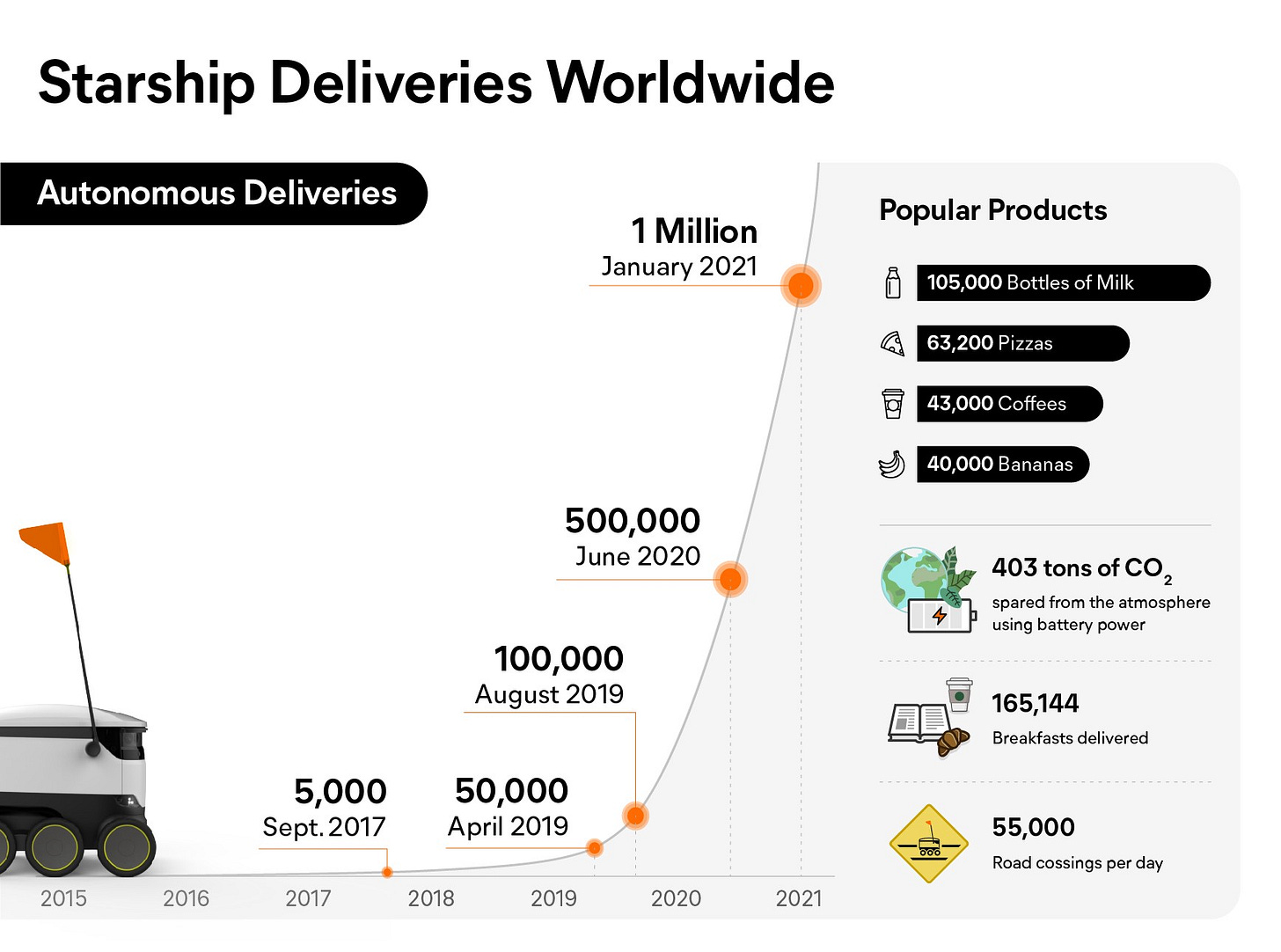

In 2014, Starship technologies started out to build self-driving delivery robots. Six years later the company crossed a very important milestone - one million autonomous deliveries. This number is up from 5,000 deliveries in September 2017. As an example, the robots deliver food and drinks from campus restaurants including Starbucks Cafe at the Bridgewater State University in the US. Starship has also secured $17M in funding lately. Here is a more detailed view about Starship’s development over the last few years:

⚒️ The future belongs to builders.

Ned Nadima from CoLab Software makes a good point in his latest article about the tools for people who build stuff: “while many builders were spending their time and energy building great tools, most of the tools they were using themselves didn’t progress as fast”.

This is especially true in today’s world when technology is moving so fast. In contrast to software engineers who can benefit from a lot of modern tools, hardware engineers are stuck with comparatively primitive tools and processes. However, in the last few years, there is an increasing amount of startups such as Shapr3D, CoLab Software, Valispace, and a few more in my landscape that are trying to change that. Valispace highlights in this presentation the disadvantages of traditional hardware development and compares them to data-driven engineering.

The future belongs to builders and I’m excited about the tools that empower people to build our future.

😎 Like a Bosch.

This is a great advertisement by Bosch showcasing the factory of the future. It combines their vision for the factory of the future with a good portion of humor. I’m not surprised that they are getting millions of clicks on Youtube for their videos. Check out the video here - a rare funny video in an industry that is sometimes a bit too serious.

💰 Ford will invest $1 billion in a German plant.

Ford targets to move to “all-electric” passenger vehicles in Europe by 2030. To do so, the company will invest $1bn to transform its Cologne facility into an electric vehicle production facility. It shows great commitment to Germany as a production site and makes Germany an even more interesting market for the production of electric vehicles. As you probably know, the construction of Tesla’s Gigafactory near Berlin is shaping up fast and VW is investing €35bn (!) in battery electric vehicles.

Let the show begin!

📈 Cobots on the rise again (?)

According to this article, collaborative robot makers will enjoy a rebound in the years to come after seeing sales fade in 2020. Due to Covid-19, revenues for collaborative robots showed negative growth in 2020 for the first time. The market research firm Interact Analysis expects those collaborative robots will expand to non-manufacturing areas such as logistics which will help Cobot makers to grow again after a difficult year.

🔮 Respect the past, invent the future.

I had the opportunity to talk at the Kreatize launch event last week in front of mid-sized manufacturers. The idea was to highlight a few entrepreneurial principles that manufacturers can learn from startups. I tried to underline how important continuous learning is and that failure is also part of the game. You usually learn the most if you fail. Besides learning, the most important point for me is the focus on people and culture. Here is the presentation and below my favorite slide:

About industrial Startups and Companies 👇

💰 Construct Capital and Ironspring launch new funds.

Good news for all the founders who are building new products and solutions in manufacturing. In the last few weeks, two new venture funds have been announced:

Construct Capital: a $140 million fund focused on investments in manufacturing, supply chain, transportation, and other foundational industries. The fund is led by two women: Dayna Grayson, a former partner at NEA where she invested in companies such as DesktopMetal and OnShape. Rachel Holt, an ex-Uber executive where she was responsible for Uber's New Mobility efforts.

Ironspring: a $61 million fund focused on industrial technologies. All three partners have a long history with industrial technologies and I got to know Ty Findley over the last years a bit. In this article, he underlined their motivation for building Ironspring: “There’s this massive gap where people forget that almost the majority of GDP in this country is manufacturing.”

📈 Manufacturing-as-a-service continues to grow globally.

There is a lot of movement in the manufacturing-as-a-service (MaaS) area in the last few months. In my last newsletter, I highlighted the acquisition of the Dutch startup 3D Hubs by Protolabs. With Zetwerk in India, there is now another MaaS startup that raised a big round of $120M led by existing investors Greenoaks Capital and Lightspeed Venture Partners. According to this TechCrunch article, the valuation is between $600-700M. The company serves around 250 customers where 25 are in the US, Canada, Europe, and other international markets. Therefore, Zetwerks plans to open offices overseas this year.

At the same time, Fictiv has raised $35M led by 40 North Ventures which brings its total funding to $92M. Fictiv describes itself as the “AWS of hardware” and is focused on prototypes and other specialized objects, not on mass-produced items.

These are just two current examples that manufacturing-as-a-service continues to grow globally. More to come.

🤑 Lotus Robotics reaches unicorn status with its latest $150M round.

Lotus Robotics has raised a $150M Series E led by Tiger Global Management and Bond. This brings the valuation of the warehouse automation company to $1 billion. The company that develops autonomous mobile robots specifically for warehouses benefits from the rapidly growing eCommerce volumes and increasingly demanding customers. It serves more than 40 customers and 80 warehouses and its LocusBots have picked more than 300 million units. Check out this video on its homepage if you want to learn more about how it works.

🔋 Sila Nanotechnologies has raised a whopping $590M round.

Sila Nanotechnologies, a US company that got started nearly a decade ago, has raised $590M led by Coatue to fund its battery materials factory. The company wants to build a factory to produce silicon-based anode material that is used in batteries. It’s no surprise that the company has secured partnerships with the likes of BMW and Daimler that are interested in that material. However, this will take time. The company expects to start production at the factory in 2024. To put this into perspective, Gene Berdichevsky, CEO of Sila Nanotechnologies, mentioned: “It took eight years and 35,000 iterations to create a new battery chemistry, but that was just step one”. If you want to learn more about tech and opportunities, you can read more here.

🤑 Dragos raised $110M to make industrial systems more secure.

Dragos develops software to detect and respond to threats facing industrial control systems. The company got started in 2016 and just raised $110M led by National Grid Partners and Koch Disruptive Technologies to grow its customer base. It has built a threat detection platform that helps operators of power plants, water, and energy supplies to defend against hackers trying to get into its operational systems. To give you an example, one of Saudi Arabia’s biggest petrochemical plants shut down in 2017 due to a cyberattack back then.

Additional thoughts on recent development

Transformation Framework

We were discussing digital transformation projects in our community meetup last week. Nadja from Körber Digital shared this four-step process (LEAD) that manufacturing companies can use for their approach towards Industry 4.0 transformation when they want to implement new solutions. You can find more info about it here. It’s very simplified so I’m looking for more detailed versions of it. If you have anything that you can share, please let me know. Below is an overview of the LEAD process:

Industry 4.0 - Reinventing the Factory Stack

There are now in total 430+ companies in the landscape, which I just updated. More to come soon.

Again, thanks to everybody for supporting this newsletter and for sending me interesting links. Feedback is always welcome 🙏

Robin