Issue #29 - The Future of Manufacturing

Topics this time: digital transformation in manufacturing course, exoskeletons, electric car production, and more money for robotics and automation startups.

👋 Welcome to Issue #29 👋

An Update on Courses & Community:

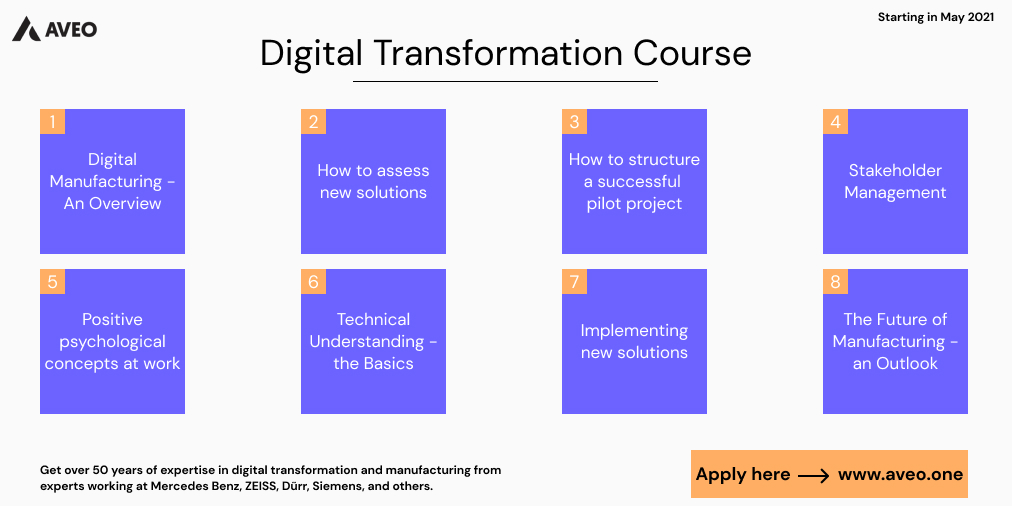

🆕 Digital Transformation Course: I’m super excited to launch the first course about digital transformation in manufacturing. This course is a 8 week, workshop-style program, with 2-4h commitment that fits your full time job. The curriculum and content of the course are based on many interviews with experts. Instructors of the course have worked at leading manufacturing companies such as Mercedes Benz, ZEISS, Dürr, Siemens, and others. Apply here or if you want to do me one favor - refer it to people who could benefit from it.

👪 Community for Innovation Managers: We crossed 100 members last week and I will invite more people over the next months. You can join the waitlist here or forward it to somebody you think should be part of this global community. As a reminder, this community is designed for people who work on the digital transformation in manufacturing companies, coordinate and drive digitization projects, and scout new ideas. Please note, building a diverse community is a key priority for me.

Got a friend or colleague interested in the future of manufacturing? Help me spread the word by sharing the newsletter if you like it!

What I’ve enjoyed reading 👇

👩🏭 GM workers are responding positively to the use of Exoskeletons.

General Motors is experimenting with strength-enhancing exoskeletons in its production facilities. Certain workers have been wearing the exoskeletons for up to 18 months now and reported improvements in their quality of life at work and improved elevated energy levels. It’s a great use case where technology can improve the lives of frontline workers while increasing employees’ productivity - something that I think is very exciting for new applications in manufacturing.

This is what it looks like in one of GM’s production facilities:

🤖 Volkswagen is ramping up its electric car production and positive image.

The digital transformation at Volkswagen is a case study itself but there is a lot of interesting news about the German automotive giant. Last week, Volkswagen overtook SAP to become Germany's most valuable blue-chip company. At the same time, a deep dive into its electric car model ID.3 by UBS Group AG analysts stacks up well against Tesla. Patrick Hummel from UBS Group summarized their findings of Volkswagen as: “the most credible EV effort by any legacy auto company so far.” So it’s not a big surprise that Volkswagen sold more fully electric cars across the globe (192,000) compared to Tesla (181,000) at the end of last year.

Finally, Herbert Diess - CEO at Volkswagen Group - is doing a great job at communicating the company’s vision, its transformation, and what they are working on. I think this also helps to improve Volkswagen’s image. Here is a good example on his LinkedIn account where he is writing about “How we transform Volkswagen”.

⚒️ Northvolt struck a partnership with Volkswagen and receives $14bn battery cell order.

Speaking of Volkswagen, the Swedish-based battery cell manufacturer Northvolt received a $14bn battery cell order from Volkswagen for the next 10 years. Northvolt has now secured more than $27 billion worth of contracts for its battery cells. This allows the company to expand its gigafactory in Sweden to achieve economies of scale that will help to decrease costs and to lower the environmental footprint.

It’s noteworthy that Volkswagen is also an investor in Northvolt and that Peter Carlsson, one of Northvolt’s co-founders, has worked several years at Tesla as VP of Supply Chain.

💰 Trumpf acquired Lantek to expand its software business.

The family-owned software specialist Lantek has been developing sheet metal software for 35 years and just got acquired by Trumpf, a German industrial machine manufacturing company. Trumpf will use the software to expand its software business and offer sheet metal processing software that is independent of the machine manufacturer. I guess this is also the reason why Lantek will continue to operate under its current name. The price of the acquisition has not been disclosed.

👉 Personal opinion: Manufacturing companies that acquire software companies is something I expect to see more in the next few years. As we all know, "Software is eating the world" and is becoming more important as manufacturing companies digitize their offerings. I've written about the M&A activity in the European Manufacturing Industry a few months ago. Looking at the results, manufacturing companies have also acquired a significant amount of consulting companies to strengthen their consultative offering and digital expertise. More to come.💉 BioNTech’s Marburg manufacturing site just got the approval to manufacture its Covid-19 vaccine.

Two days ago, the European Medicines Agency approved that BioNTech can manufacture its Covid-19 vaccine at the facility in Marburg (Germany). From manufacturing the mRNA to the bulk drug substance 50k steps are required. The speed at which they have set up the production and supply chain is incredible. BioNTech plans to produce 250 million doses in the first half of this year which means they have to produce 20 million doses per week from now (8 million doses are already produced).

🏭 Apple is about to make a deal with Hyundai-Kia for autonomous vehicles.

There has been a lot of speculation about the “Apple Car” in the last few years. According to multiple sources, Apple is close to finalizing a deal with Hyundai-Kia to manufacture an Apple-branded autonomous vehicle in Georgia (US). In theory, Apple could partner with different automotive players. However, finding one that has manufacturing capabilities in the US and lets Apple control the software and hardware is not easy. That’s why Hyundai-Kia is interesting which seems to be open to that. Hyundai-Kia could also accelerate the development of its own autonomous and electric vehicle plans through that partnership. No agreement has been reached but this is going to be interesting to watch. Tapping into the $10 trillion (!) mobility market unlocks huge potential for Apple that owns roughly one-third of the $500bn smartphone TAM.

🎮 Amazon is expanding its elements of gamification for warehouse employees.

Amazon introduced elements of gamification for its warehouse employees in 2019 and is now expanding the program to warehouses in 20 states. The program remains completely optional but workers at the station can now choose from one out of six games. One game was described as “Tetris, but with real boxes” according to this article. Some workers like the games because they can help cut down on the tediousness and repetition of tasks. Some workers are afraid that these games will push employees to work faster and thus risking injuries.

🧐 Autodesk shamelessly replaced nTopology logo on social media

Mark Chester used nTopology and Autodesk Fusion 360 to build a model of Concept Cricket Gloves. He shared that model with the nTopology logo on Twitter. Later, Bradley Rothenburg, CEO of nTopology, found that Autodesk used the same picture on social media but replaced the nTopology logo with the Autodesk logo without giving credits to nTopology. In the meantime, Autodesk apologized and updated the post. I still share this anecdote because it happens too often in this industry that young and innovative companies do not get enough credit for the work they are doing. See yourself:

About industrial Startups and Companies 👇

💰 Katana raised an $11M Series A led by Atomico.

Katana is building a manufacturing-specific ERP software for SMBs and has raised $11M led by Atomico which brings its total investment to date to $16M. Andreas Helbig and Ben Blume from Atomico have written more about why they invested in Katana here.

Katana has developed a Plug'n'Play ERP specifically for smaller manufacturing companies. It helps these companies to track raw material costs, inventory movements and to get a status overview. It also offers integrations into tools such as Shopify, WooCommerce, and QuickBooks. Shopify is very interesting for Katana since a boutique manufacturer that sells on Shopify can directly pull orders from Shopify into Katana. At the same time, being listed in the Shopify AppStore is a great distribution channel for Katana.

🤑 Full Speed Automation raised a $3.2M seed round led by HCVC.

The former Head of Core Automation Engineering at Tesla, Luc Leroy, has raised a $3.2M round for his new company Full Speed Automation. The round is led by HCVC and will help the company to speed up the development effort for its software platform. The platform can be described as a “no-code automated manufacturing platform” that will help manufacturing companies to simplify “data acquisition and enable production monitoring with real-time telemetry”. The platform can be compiled and deployed in seconds and integrates into existing production lines. As you see, the company name speaks for itself and it’s all about full-speed automation.

🤑 First Resonance adds Blue Bear Capital as a new investor.

First Resonance raised a new round led by Blue Bear Capital which brings its total investment to $5.3M. The company develops a manufacturing platform to coordinate hardware development processes and has grown from zero customers at the beginning of last year to 17 customers today. Engineers and technicians can collaborate on the platform and get real-time visibility.

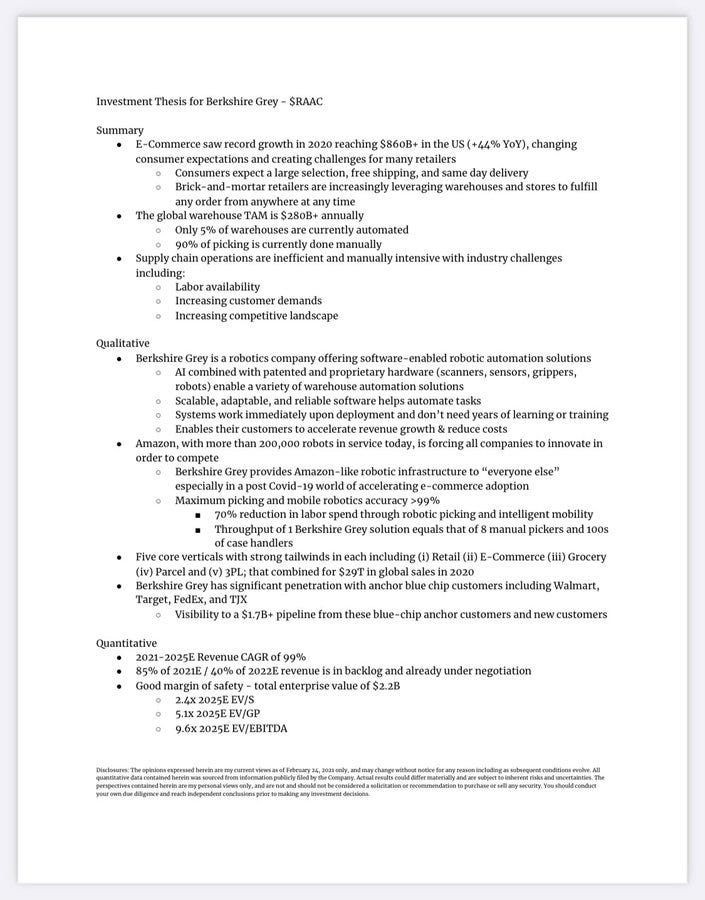

🤑 Berkshire Gray to go public via SPAC.

Berkshire Gray develops materials handling systems for warehouses plans to go public by way of SPAC. The deal could value the company at up to $2.7bn.

A SPAC is a “Special Purpose Acquisition Company” and formed to raise money through an initial public offering to buy another company (read more here if you’re interested).

Below is the investment thesis from Chamath Palihapitiya who helps to bring Berkshire Gray public (see Tweet here):

🤑 Nimble Robotics raised a $50M Series A led by DNS Capital.

Nimble Robotics is one of the companies that benefit from the record growth in eCommerce and fulfillment. The company is developing robots that can pick, pack and handle products within warehouses. To deploy more robots to its customers, Nimble Robotics has a $50M round. The company counts several Fortune 500 fulfillment centers to its customer base and was founded from the Artificial Intelligence labs at Stanford and Carnegie Mellon.

🤑 AM Ventures targets €100M fund to invest in 3D printing startups.

AM Ventures is a new Munich-based fund that focuses on investing in industrial 3D printing companies. Until today, the fund has already invested in 15 startups across 6 countries and is targeting an initial closing of €100M. The main company and major shareholder behind the fund is Langer Group, a German mold, and tool manufacturing company.

Shopfloor IT Summary

Together with Marco Holst from ZEISS, we hosted a workshop for our Future of Manufacturing Community about shopfloor IT, the basic terms, historic development, and future outlook. Here are the main takeaways from our discussion we had after the workshop:

Automation: In many cases, factories are still far away from automation and are struggling with basic automation. Many people see the term “industry 4.0” more as a pure marketing term. The complexity on the shop floor is a big risk and makes it hard to quickly implement new solutions. It’s similar to how banks have been (and some still are) running on the technology they started with 30 years ago. In addition, factories are not only about machines since humans play a very important role. Flexibility is often used as another argument against automation.

Enterprises vs. SMEs: while large enterprises in manufacturing invest significant resources in the digital transformation, projects can take a long time. SMEs might be faster but sometimes lack the knowledge or resources for a big transformation. Also, changing a running system can be such a big change for SMEs that people are too afraid of it.

Machine data: when it comes to getting data from machines people had very different experiences. One person who is building an MES in additive manufacturing mentioned that it is fairly easy to get data from machines. On the opposite, one person working at a traditional discrete manufacturing company mentioned that it’s very hard to get data from machines and some machines are still not connected to the software running in the factory.

Industry 4.0 - Reinventing the Factory Stack

There are now in total ca. 450 companies in the landscape, which I just updated in March. More to come soon.

Again, thanks to everybody for supporting this newsletter and for sending me interesting links. Feedback is always welcome 🙏

Robin