Issue #8 - The Future of Manufacturing

Welcome to Issue #8. I have been on vacation in the mountains for 2 weeks which is why this issue comes a bit later than usual. This time, I'm focusing on productivity, a number of big acquisitions in the industry, 3D printing and the growing importance of platforms.

💡If you are working on anything in manufacturing and would like to get some feedback, feel free to reach out. 💡

I hope you enjoy reading it and if you do so, any feedback, shares or links are much appreciated!

Disclaimer: thoughts and opinions expressed in the newsletter are my own.

What I enjoyed reading

#productivity#

👷♀️ I'm spending a lot of time looking at macroeconomic trends and their implications for the manufacturing sector. The relatively low unemployment rate is definitely one. This article in the NYT highlights that a low unemployment rate can force companies to re-engineer their processes to increase productivity. This opens up a great window of opportunity for entrepreneurs in my eyes, building tools for these companies to increase productivity.#inspection#

🤔 Regarding tools for workers and engineers to improve workflows, Anna-Katrina who is the CEO of Instrumental, gave a talk about automating intelligence in manufacturing. Her talk is centered around better outcomes and how data and the right tools for engineers can help manufacturing companies to achieve better outcomes, i.e. better yields, time to market and quality. One of their customers is using Instrumental to take images on the line and to identify defects. Engineers look at the images and can use software to deploy ML without programming by identifying failures and setting up rules so new units will fall off the line if they fail the test.#ecosystem#

📰 Bloomberg wrote a longer article to answer the question "why can't Europe do tech?". It's the same story you often hear ... Europe is lagging behind and big tech companies are missing, which is also true. They also highlight some industrial companies such as Lilum or Volocopter but I think the article is quite superficial. It misses highlighting the strengths of the continent (e.g. engineering knowledge), the challenges (e.g. less entrepreneurial mindset sometimes) and how this can play out in the future.#automation#

📦 Automation is happening and warehouses are a very interesting application for automation (think of all the pick'n'place tasks for example). The Chinese eCommerce firm JD has built a nearly autonomous warehouse - they need only 4 employees for handling and monitoring the robots. So they can handle 200,000 orders a day with 4 employees, quite impressive.#trends#

📈 Lastly, here is a quick video by Goldman Sachs where they share their view on the factory of the future. Goldman Sachs estimates that the digitization of factories could save $500bn for manufacturers and customers. In total, they see the following three trends:

1) Virtual ecosystems and that a lot of things will be done virtually e.g. prototyping

2) Human-machine collaboration e.g. with cobots

3) Real time communication including remote control

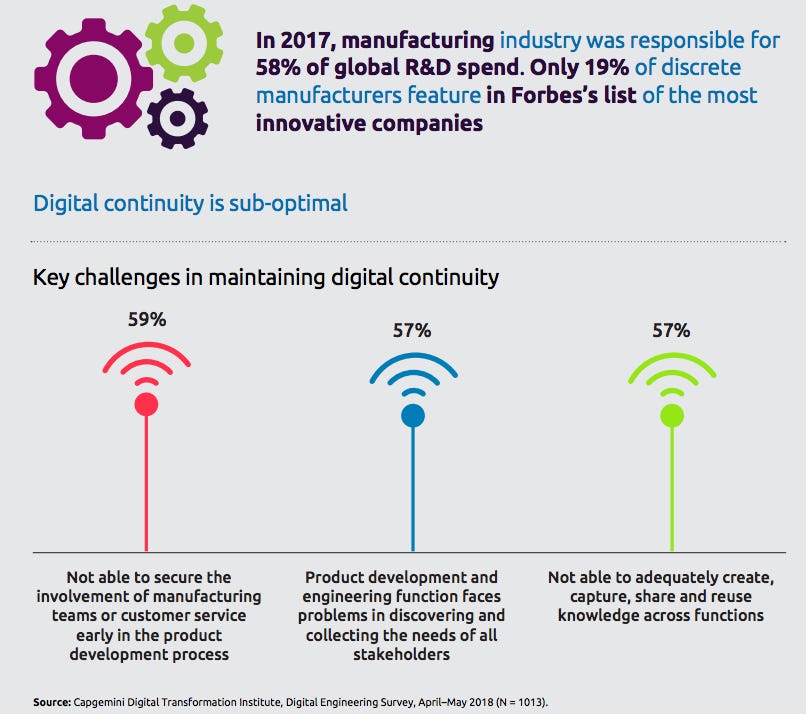

If you need more numbers to these trends, Forbes summarized the Digital Engineer study by Capgemini. It's going to be BIG!

About industrial Startups and Companies

#acquisition#

🤑 Relayr, a German startup that is offering industrial IoT solutions, was acquired for $300M by MunichRe. The five-year-old startup will continue to operate independently and has been partnering with MunichRe for already 2 years. That's great news for the overall ecosystem and it shows that big exits are possible in this industry.#acquisition#

🤑 Siemens joined MunichRe in acquiring a big industrial startup. To strengthen its own IoT portfolio including MindSphere they bout the low-code platform Mendix for staggering $700M. The trend of low-code platforms continues where enterprise companies try to enable all of their employees to build applications without deep programming knowledge. Mendix raised $38M in total according to Crunchbase from investors such as Battery Ventures.#acquisition#

😲 Nidec, a Japanese motor maker, is about to buy 5 (!) German robotics companies over the next months. The total deal volume is about $450M. The goal is to produce its own robot parts and expand sales to Europe. I think this has been mostly under the radar but it shows the appetite for German high-tech companies.#funding#

🏭 DyeMansion, a 3D printing startup based in Munich, raised €5M from UVC Partners, b-to-v and AM ventures. The company is focusing on post-processing in 3D printing, meaning that they transform raw, 3D-printed parts into high-value consumer and industrial products. The company has more than 400 customers including BMW and Under Armour.#funding#

📇 Jumping from seed to growth, Formlabs, a startup that makes affordable 3D printers, raised an additional $15M from NEA and just entered the unicorn club. While doing so, they also could convince former GE CEO Jeffrey Immelt to join the board. Jeffrey Immelt who already pushed into 3D printing at GE also sits on the board of DesktopMetal.

Additional thoughts on recent development

Platforms and AppStores #platform#

My colleague Clement wrote a great piece about the growing importance of app marketplaces in the B2B landscape. I think this is very relevant for the manufacturing sector although I think it will take some time until we really see the first winners of these platforms. As I wrote already in my article, instead of trying to build a platform first, I think founders should start with a narrow use case first and develop the product with the goal of having a platform in the long run. People don’t buy IoT and don't buy platform-first, they buy a solution to a problem.

Industrial Landscape #landscape#

I made a big update to my industrial startup landscape and added 30 companies. The next update will come in a few weeks with already 20+ companies on the last. 'It's getting hot in here.

Thanks to everybody for supporting this newsletter and for sending me interesting links. As always, any input, shares, and feedback are always warmly welcome 🙏

Robin