Issue #30 - The Future of Manufacturing

Topics this time: labor shortage in manufacturing, vision technology, Industry 5.0, the rise of robotics startups, and a few massive funding rounds.

👋 Welcome to Issue #30 👋

An Update on Courses & Community:

🆕 Digital Transformation in Manufacturing Course: We have launched our first course about digital transformation in manufacturing. This paid course is a 8 week, workshop-style program, with 2-4h commitment that fits your full time job. Instructors of the course have worked at leading manufacturing companies such as Mercedes Benz, ZEISS, Dürr, Siemens, and others. It’s a unique combination of VC/Startup and industry expertise.

We have 3 more slots available to everybody who could benefit from the course - independent of the role or job title. More info here and you can register here.👪 Community for Innovation Managers: We recently crossed 100 members in our community and I will invite more people over the next months. You can join the waitlist here or forward it to somebody you think should be part of this global community. As a reminder, this community is designed for people who work on the digital transformation in manufacturing companies, coordinate and drive digitization projects, and scout new ideas. Please note, building a diverse community is a key priority for me.

Got a friend or colleague interested in the future of manufacturing? Help me spread the word by sharing the newsletter if you like it!

What I’ve enjoyed reading 👇

👩🏭 Labor shortages in manufacturing in the US are not getting better

Timothy Aeppel from Reuters underlines that the labor shortage for US manufacturers has been particularly frustrating in the past year. While Covid-19 pushed millions of people out of work, most of them have been working in the service industry. Factory employment is only 4% below pre-pandemic levels. At the same time, many factories have seen an increase in demand. Without additional employees, it’s hard to keep up with it. There is a big mismatch in the labor market between those out of work and factory jobs - a job in a factory is very different from working in the service industry. So a significant number of vacancies go unfilled which translates into lost business.

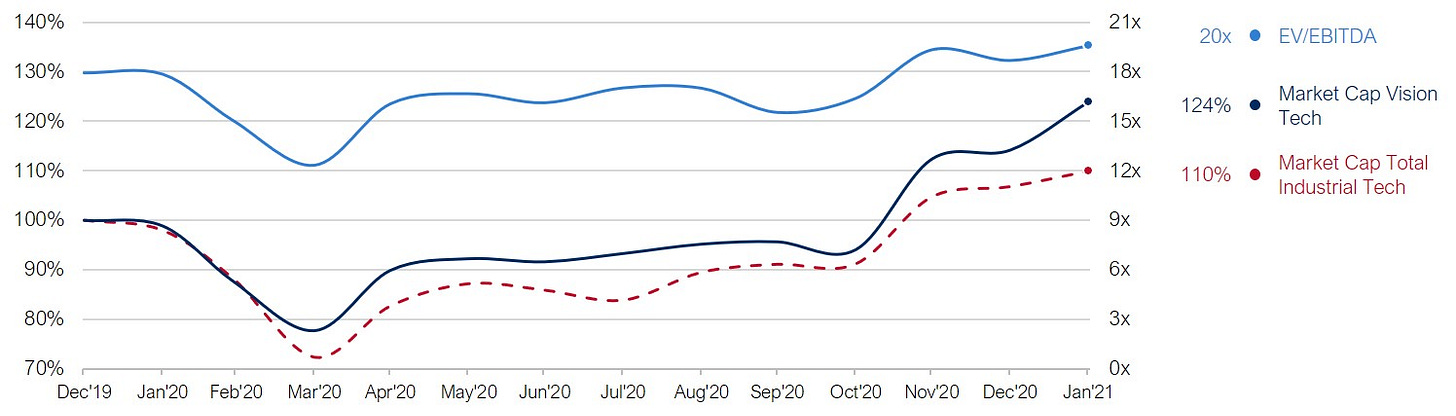

🤖 The market capitalization of Vision Technology vs. Industrial Tech companies

The corporate finance advisory firm Capitalmind has published an overview of the market capitalization of Industrial Technology compared to its subsegment Vision Technology. Both segments have been affected by market challenges such as Covid-19 and the US-China relationship. However, Vision Technology companies suffered less throughout the last year and could even outperform the overall index recently. Vision Technology plays an important role in automation solutions that include quality inspection, vision-guided robots, or machine control for example. The article also highlights two case studies if you want to learn more.

To make it more visible, here is the development of the indices in the last 15 months:

🏭 BMW and NVIDIA have built a next-level virtual factory planning tool

The automotive giant BMW has built a virtual factory planning tool together with NVIDIA that is basically a complete virtual representation of the factory. The tool can integrate with various data sources, applications and enable real-time collaboration. To better understand how it works and what it can do, I really recommend watching this video. The photorealistic quality is impressive and it looks indeed like the future of virtual factory planning.

🏭 Intel will invest $20bn in two new factories and manufacture chips for other companies

Intel recently announced that it will invest $20bn in two new factories in the US. The more interesting piece about the announcement is that Intel wants to manufacture chips for external chip designers, ie. offer chip manufacturing-as-a-service. This means that Intel will become a foundry itself and the company estimates this could be a $100bn opportunity by 2025. The model underlines the importance of flexibility when it comes to manufacturing capabilities. According to Intel’s CEO, “it won’t be unusual for Intel to ask Qualcomm if it can make its chips, or have the same conversation with Apple.”

👩🚀 Microsoft scores a massive deal with the US-Army for its HoloLens-based headsets

Enterprise contracts can be very big but whoever made that deal at Microsoft with the US Army will probably have made the deal of her/his life. Why? Microsoft will equip the US Army with HoloLens-based headsets in a deal that could be worth up to $21,88bn over ten years. This means that Microsoft will supply 120,000 headsets to the US Army. Is this a turning point for mass adoption of mixed reality? It certainly is a good data point but the collaboration between Microsoft and the US-Army is also very specific. Microsoft has been working with the US-Army since 2018 on what they call “Soldier Centered Design”. As an example, the system enables life-like mixed reality training environments. While it’s very interesting from a technology point of view, there has been strong resistance from Microsoft employees on that collaboration.

🤖 Observations on robotics startups

Robotics startups can face added complexity compared to enterprise software startups. This added complexity comes from building integrated hardware <> software solutions, capital requirements for hardware purchases, complex implementations, and lengthier proof of concept phases. Sam Baker, VP at Scale Venture Partner, wrote down his observations on robotics startups and recommendations for founders of robotics startups to find product-market fit. His main takeaways are:

Solve one very specific problem: think small and demonstrate that your system can automate one specific task very well. Most robotics solutions do not handle a broad range of tasks but focus on one specific task.

Focus on high-frequency tasks: if you solve a high-frequency problem that is central to the system, you will most likely deliver a lot of value to your customer. This brings us to the next point.

Demonstrate tangible ROI: put numbers behind the value you are creating. Companies do not buy robots, they buy a solution to a problem and want to understand the benefits of the solution. To add to that from my own experience, I think “time-to-value” is a very important KPI when selling to manufacturing companies.

Balancing costs, sales cycle, and unit economics: the upfront investment can be (much) high compared to traditional SaaS companies. One way to tackle this is by trying to raise a bigger round initially. Also, the revenue is often a mix of subscription fees and (significant) service revenue.

Decrease implementation efforts: while this might be hard in the early days, try to share some of the implementation efforts with your customers once your system is more mature.

Become the system itself: once you have automated one specific task, try to extend that to become an operating system itself. A good way to do that is by integrating with other systems or data sources to optimize the operations as a whole.

About industrial Startups and Companies 👇

🤑 ForwardX Robotics raised a $38M Series B.

ForwardX Robotics, a China-based company that develops autonomous mobile robots (AMR), raised a $38M Series B led by CDH Investments’s VGC. That money brings its total funding to more than $63M. The company’s mobile robots can have three functions: pick’n’pack workflows, moving heavy payloads, and moving pallets.

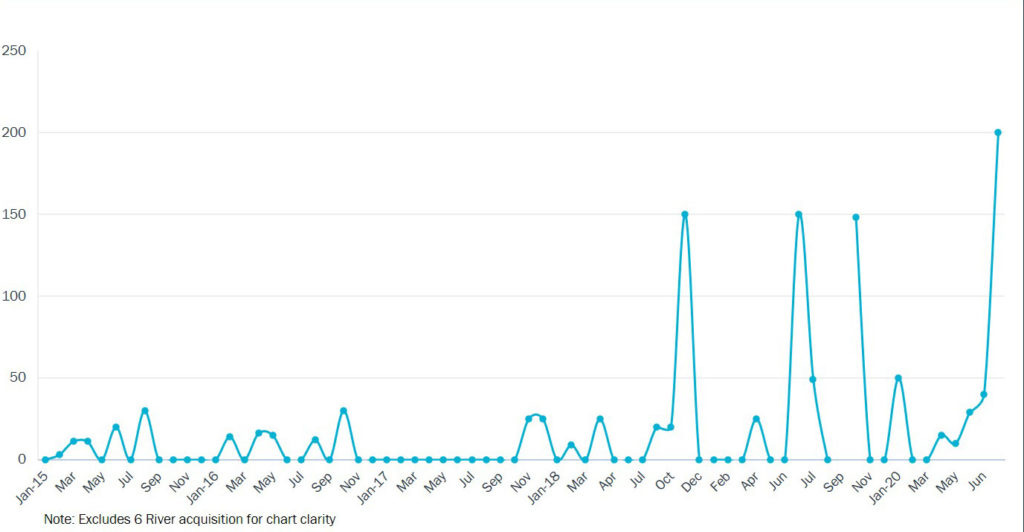

ForwardX Robotics is one out of many robotics companies that benefit from the rising need for flexible and autonomous mobile robots. Other companies that have raised significant amounts of money are Geek+ and GreyOrange for example. Here is an overview of investments in AMR companies in $M over time (from July 2020):

🤑 Fortify raised a $20M Series B led by Cota Capital.

Fortify secured $20M to speed up the development of its 3D printers, and to accelerate expansion. Fortify has developed a Digital Composite Manufacturing platform that enables the company to produce custom microstructures in high-resolution 3D printed parts. It shipped the first 3D printer last October. It also works with material partners on high-value material development programs. The company wants to tap into verticals such as injection mold tooling and continue to strengthen its position in end-use electronic devices. To do so, Fortify was able to hire a few very experienced people from other 3D printing companies such as DesktopMetal and Stratasys.

💰 Eclipse Ventures raised its $500M Fund IV.

Eclipse Ventures, a US-based venture fund focused on the digital transformation of “essential industries” including manufacturing, has closed its fourth fund of $500M. With 7 investing partners in the team, Eclipse has now nearly $2 billion under management. The fund counts industrial startups such as Augury, Instrumental, Bright Machines, and Symbio to its portfolio.

🤑 Lilium goes public via SPAC.

In my last Newsletter, I was highlighting Berkshire Gray that goes public by way of SPAC. Next up is the Munich-based flying taxi startup Lilium.

Lilium will merge with Quell Acquisition, a SPAC founded by a former GM executive. The SPAC deal will value Lilium at $3.3bn equity value. The company is expected to receive $830M from that deal - enough money to continue building its flying cars.

At the same time, Lilium unveiled a new seven-seater jet. This jet is supposed to have a top-seed of 175mph and a range of 155 miles.

🤑 Robotics firm AutoStore receives $2.8bn investment by Softbank

Another massive deal is Softbank investing $2.8bn in AutoStore, valuing the company at $7.7bn. AutoStore got founded 25 years ago and has developed what it calls “cube storage automation”, a specific system that maximizes storage space in warehouses. The company has developed 20,000 of its robots at 600 sites already and counts companies such as BestBuy and Siemens to its customer base.

My dear friend Nathan Benaich describes the success of these robotics companies very well in this article: “AutoStore, amongst peers like Berkshire Grey, Ocado Robotics, and 6 River Systems, are almost 10-20 year ‘overnight’ success stores in robotics,” he said. “They’ve quietly been building out their capabilities and warehouse footprint over that time and are now aggressively capturing today’s surging customer demand.”

Here is a picture of the system installed at Boozt:

🤑 SwipeGuide raised a €5M round led by Speedinvest

SwipeGuide, a company that develops work instruction software, has raised a €5M round led by Speedinvest together with CapitalT. Manufacturing workers can create, share and track digital work instructions by using Swipguide and use the tool for on-the-job training. Oftentimes the software replaces paper and pdfs. Its software is used in more than 200 factories today with more than 30,000 users for companies such as PepsiCo, Heineken, and ABB.

Podcast: Empowering Workers to Innovate

I sat down together with Trond from the Augmented Podcast to talk about empowering workers to innovate. You can listen to the podcast here (38min).

We talked about:

How to define manufacturing innovation? Why is it relevant now?

Why should young people be excited about manufacturing?

Why is upskilling so fundamental? How to scale upskilling?

What should people know about our 'The Future of Manufacturing' community?

Industry 4.0 Map - Reinventing the Factory Stack

There are now in total nearly 500 companies in the landscape, which I just updated in April. More to come soon.

Again, thanks to everybody for supporting this newsletter and for sending me interesting links (Nathan 👋, Philipp 👋, Christian👋). Feedback is always welcome 🙏

Robin